Construction work is one of the most dangerous professions. In 2019, construction fatalities increased by 5%, and unfortunately, 1,061 construction workers died on the job. Construction work will always have its hazards. Paying attention to construction site safety and construction worker safety training can help to reduce these alarming statistics.

Safety Risks In the Construction Industry

Injuries frequently occur in the construction industry because job sites are full of hazards. Almost every day, construction workers find themselves in risky situations and need to take precautions. Many of the tools and equipment workers use are dangerous without proper training and handling. Though the potential for injury varies greatly according to factors such as the type of work, most construction site injuries fall within four categories.

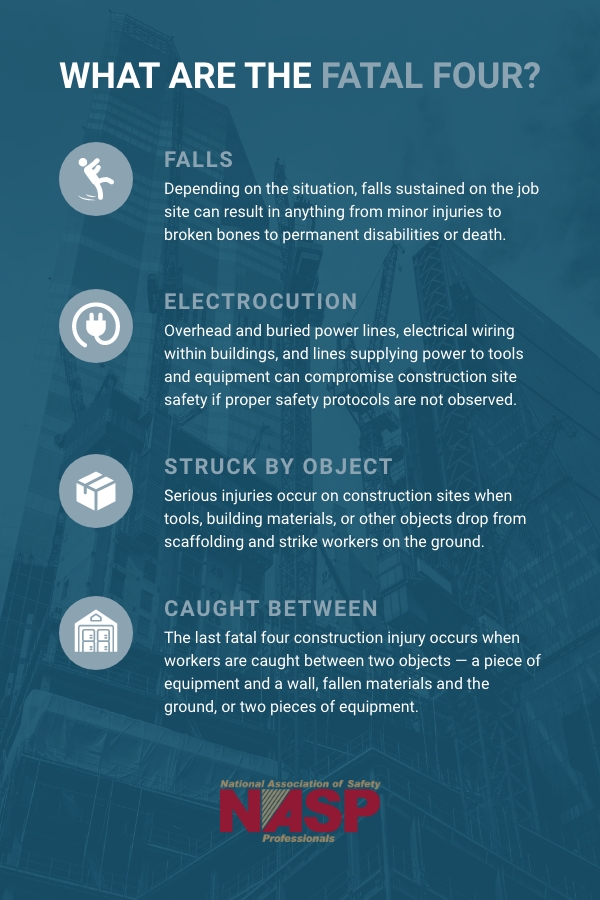

What Are the Fatal Four?

The “fatal four” causes of construction injuries are job site hazards that, when combined, result in at least 57% of construction site fatalities. Injury and death from fatal four accidents can be reduced through training and following proper safety precautions. The fatal four include:

- Falls: Whether building a skyscraper or installing a roof on a residential building, construction workers often conduct their work at high heights. Depending on the situation, falls sustained on the job site can result in anything from minor injuries to broken bones to permanent disabilities or death.

- Electrocution: Overhead and buried power lines, electrical wiring within buildings, and lines supplying power to tools and equipment can compromise construction site safety if proper safety protocols are not observed. Even those not working directly with wiring or other electrical components must exercise caution because electricity is everywhere on a construction site, and electrocution kills about 143 construction workers every year.

- Struck by objects: Serious injuries occur on construction sites when tools, building materials, or other objects drop from scaffolding and strike workers on the ground. Workers can also be struck by equipment like forklifts, backhoes or cranes. These injuries can even occur when workers carrying lumber or other items hit others by mistake or when workers are struck by trucks or other vehicles.

- Caught between: The last fatal four construction injury occurs when workers are caught between two objects — a piece of equipment and a wall, fallen materials and the ground, or two pieces of equipment. Injuries resulting from these situations can be quite severe, often fatal.

Other Risks to Construction Workers on Site

The fatal four construction injuries might be the most common, but they are far from the only injuries that can occur on the job site. Other common causes of construction site injuries include:

- Cuts and abrasions: Cutting materials to size is one of the most common activities on any construction site. Without proper precautions, it’s an activity that can lead to varying degrees of injuries. Workers frequently employ everything from utility knives and hand saws to tables saws. Cuts from some power tools can result in severe injuries.

- Burns: Construction workers must be cautious about burns from several sources on the job site. Thermal burns occur when the skin comes into contact with a hot object like hot asphalt or tar, a piece of equipment, or an open flame. Scald burns occur when hot liquid or steam, which could come from a burst pipe or a piece of machinery, comes into contact with the body. Electrical burns are associated with wiring and power lines, and chemical burns occur when certain toxic substances touch the skin.

- Exposure to dangerous chemicals: Solvents, acids, paint thinners, pesticides and many other chemicals used by the construction industry can cause burns and many other injuries. Some of these substances are dangerous to the skin, while others are eye irritants. Some are dangerous to breathe in enclosed spaces, and others are dangerous to breathe at all. It can be difficult or impossible to detect the presence of some chemicals, making construction safety training regarding these substances all the more crucial.

- Trench injuries: Excavation is another common construction site activity, and it’s another that can lead to injury without proper training and safety measures. Trench collapse can trap and suffocate workers if trenches are not properly reinforced and sloped. Workers in trenches can also encounter buried pipes and power lines that can pose a serious danger if struck.

- Dehydration: Not all serious health risks come from construction site materials. Dehydration is a major concern for anyone working outdoors, doing prolonged physical labor, or working in the heat. When more water is lost through sweat than is consumed, headaches, dizziness and fatigue can occur. These symptoms increase the likelihood of falls and other injuries. While dehydration is generally easy to remedy, it can become dangerous if left unchecked. Serious dehydration can cause drops in blood pressure, fever, increased heart rate, delirium and unconsciousness.

Of course, these are just examples of the most common injuries on job sites. Depending on the nature of the job, many other potential hazards could be present. While the statistics regarding construction injuries paint a grim picture, the good news is that with proper construction safety management — including the training of construction workers, forepeople and supervisors — many of these injuries can be avoided.

Find out how to devise a safety plan and institute a construction safety training program that protects workers, keeps costs down, and keeps your company OSHA compliant.

Creating a Construction Safety Plan — Avoiding Common Injuries

The main goal of any safety plan for a construction site is to keep workers protected. Armed with knowledge about the most common construction site safety issues, you can begin planning to avoid them — and training others to do the same.

How to Create a Construction Safety Program

When one out of every five worker deaths occurs in construction, a safety plan for the construction site is essential to protect workers and keep the construction company financially viable. Here are some important steps for developing a comprehensive construction safety program.

- Create a training schedule and make time for training: Training is at the heart of safety because workers can only observe safety practices if they’re aware of them and why they’re important. Keep a file for each employee and record their completion of each stage of the safety training. New employees should receive safety training prior to working on the job site, and even the most seasoned employees should periodically receive refresher courses in construction safety training.

- Identify employees with the desire and aptitude to earn safety certificates: Managing job site safety can require multiple safety professionals. It’s always useful to have a certified Scaffold Safety Specialist or a Blood-borne Pathogen and First Aid Treatment Specialist on site. Having employees with the knowledge and experience to supervise certain activities safeguards workers against accidents and avoids delays on the work site.

- Keep informed of changing OSHA requirements: The Occupational Safety and Health Administration (OSHA) frequently updates its rules to provide a safer environment for workers. It’s essential to make yourself aware of these changes and to make any necessary adjustments to avoid OSHA fines or worker injuries that could have been avoided. OSHA requirements have a major impact on construction site safety programs and practices. Your safety program will need to be OSHA compliant, and your job sites need to pass OSHA inspections.

- Tailor your safety plan for the construction site: Every construction job presents different challenges, and even the most routine job may need special consideration if the unexpected happens. Likewise, safety plans must be adjusted according to the site, the project, the materials and tools required, and many other variables. This could mean learning to use new personal protective equipment (PPE) or even leading a training course before operating a new piece of machinery. Before each job, you should assess its unique needs in terms of safety, formulate a job-specific safety plan, and review the plan thoroughly with your employees.

- Conduct regular inspections: Make it standard practice to inspect materials and tools at the start of the workday. Build time into your schedule to conduct more detailed inspections of power tools and heavy machinery.

- Take employee concerns seriously: Let employees know their voices will be heard when they express concerns about their safety. When they do, investigate the situation and make an improvement plan. When employees feel validated in their concerns, they’ll be much more confident about their safety at work, and they will hold each other accountable for observing best safety practices.

- Adjust your program as needed: No safety program is set in stone, and if something isn’t functioning optimally to protect you and your coworkers or employees, it needs to change.

- Go beyond the bare minimum: Meeting OSHA requirements are important. They should be considered the least you can do to ensure safety on the job site. One way to exceed OSHA construction safety standards and regulations is by undergoing specialized training in safety management which meets or exceeds OSHA standards.

- Lead by example: You and other site supervisors should know OSHA site safety regulations inside and out and practice them to the letter. When workers see that their supervisors are following the safety protocols and that the rules apply to everyone, they’ll be much more likely to comply. Fostering an environment where safety is everyone’s concern leads to fewer accidents and injuries, employees who look out for one another and feel supported by their supervisors, and a job site where best safety practices become second nature.

- Become a certified safety manager: Creating and maintaining a safety culture in construction isn’t always easy. As a construction safety professional, you can improve your skills and learn the best techniques to keep your team safe by becoming a Certified Safety Manager in Construction. With this certificate, you can teach safety courses to other employees, design and manage safety programs, implement OSHA guidelines for construction safety, interpret regulations, avoid civil and criminal liability, and most importantly, keep injuries to a minimum.

Construction Site Safety Precautions

A basic understanding of the most common hazards and causes of injuries and how to avoid them will help you understand where you need to focus your attention and where your team may need more training.

Managing Tool Safety

The improper use of tools undermines construction site safety. Prolonged misuse of tools can lead to long-term health conditions for workers, such as carpal tunnel syndrome, tendonitis, back and posture problems and trigger finger. It’s never worth cutting corners when using tools, and saving a few minutes isn’t worth the risk of injuries or developing problems down the road. A few things to keep in mind when using tools on the job site:

- Always examine tools before use: Do not use tools that are worn or damaged.

- Use the appropriate tool for the job: Using tools for tasks outside their intended purpose can cause safety hazards.

- Familiarize yourself with new tools before use: This includes reading and understanding any safety manuals that come with the tool and ensuring employees who will use it have the required training. Always follow the guidelines put in place by your construction safety plan.

- Never tug on cords or drag a tool by its hose: Additionally, make sure cords and hoses stay clear of damage from sharp objects, heat, open flames and chemicals.

- Use the recommended PPE: Follow your construction safety program guidelines and use the required personal protective equipment.

- Don’t become distracted while using tools: Many injuries occur when tools accidentally contact wiring, power lines, pipes or other workers. Remind employees to always be aware of their surroundings.

- Keep tools off when not in use: Always turn off or unplug power tools, nail guns and other power tools when they’re not in use to avoid injury from accidental discharge.

Become a Hand Tools and Power Tools Specialist to learn more about tool safety on the job site and strengthen your skills as a safety manager.

Preventing Falls

Falls are the most common of all construction site injuries — of the fatal four, falls are the most frequent and are the number one cause of fatal injuries in the construction industry. Scaffolding is a common sight at job sites, and 2.3 million people on construction sites work on scaffolding, so it’s crucial to take precautions. Following a construction safety program to eliminate falls can protect workers, save money, prevent downtime and even potentially save lives. Your workplace should take many precautions to prevent falls, including:

- Erect scaffolding correctly: It must support its own weight and at least four times the maximum anticipated load. Scaffolding should never be overloaded, and it should always be erected and torn down under the supervision of someone with proper training.

- Ensure scaffolding is stable and structurally sound: Scaffolding should never be propped up with portable objects like barrels, crates or lumber. Examine it for defects that could pose a safety issue. Never use worn or damaged scaffolding. Platforms, guardrails, midrails and toeboards must meet all safety requirements. Brackets, rails, ropes and trusses should be replaced immediately if they become worn or damaged.

- Keep scaffolding away from electrocution hazards: Scaffolding must be placed a minimum of ten feet from power lines.

- Keep ropes secure: Be mindful of heat and sharp objects around natural or synthetic scaffolding ropes.

- Eliminate tripping hazards: Keep scaffolding free from any debris that could present a tripping hazard. In general, scaffolding should be kept clear of tools and materials.

- Avoid wet conditions: Scaffolding should not be used in bad weather, especially when it is wet or icy. Wet conditions pose a greater risk for workers to lose their footing or slip.

- Educate workers on how to work on scaffolding: Practicing good posture can reduce the risks of falls from scaffolding. Also, never lean over the rails of the scaffolding to reach for items.

- Examine ladders and stairs: Inspect them for any signs of wear or instability before use.

- Use the correct size ladder: Always use a ladder that is at least three or four feet higher than the destination you need to reach, and avoid standing on the top rung of a ladder.

- Place ladders correctly: Place ladders on a stable foundation where they won’t slip. Be mindful of using ladders around water or on windy days.

- Never overreach: Instead, move the ladder every three to four feet or as needed. It’s well worth taking the extra time to move a ladder if it prevents workers from losing their balance and risking a serious injury from a fall.

- Use fall protection PPE: Use fall arrest systems such as body harnesses and safety nets when working at a significant height, whether on a ladder, aerial lift or scaffolding.

Preventing Electrocution

Though construction sites could not operate without electricity, electricity can be deadly, and it must be handled cautiously. Many electrocution injuries occur when workers or machinery accidentally strikes a power line or buried cable. Other hazards come from operating electrical power tools or performing electrical work on a construction project. When you run your construction safety training, include best practices for avoiding electrical injury, such as:

- Ensure all tools are operated from a ground fault circuit interrupter grounded power source — especially if the tools are being operated in wet conditions.

- Cords, cables and outlets should be inspected regularly and replaced if worn or damaged.

- Always unplug power tools when not in use.

- Temporary construction site lighting should be equipped with nonconductive guards.

- Take all necessary precautions when working near power lines, buried cables or electrical wiring inside buildings.

- Ensure workers are mindful of their surroundings and the activities of coworkers.

To learn more about the common electrical threats to workers and how to avoid them, become an Electrical Safety Specialist for your workplace.

Operating Heavy Machinery Safely

Due to their size and power, machines like cranes and forklifts are capable of causing devastating injuries very quickly. Too often, a single strike from such a piece of equipment can be all it takes to cause a tragedy on a job site. Precautions to avoid injury when working with heavy machinery include:

- Anyone operating a piece of heavy machinery like a crane or forklift should be fully trained for their job and certified when necessary.

- These machines should never be left unattended, and the keys should never be left in the ignition.

- Always make sure you have adequate space to maneuver the machinery — account for your swing radius and how much room you need to turn the equipment.

- Alert others on the construction site to your movements when operating machinery.

- Take extra care when reversing a forklift or similar piece of machinery and double-check to ensure the area is clear of other people.

- Practice caution when going around turns or up and down hills and slopes as your line of sight can be obscured.

- When necessary, have another worker to act as a spotter when an equipment operator navigates equipment where their vision might be limited.

- When getting into or out of heavy machinery, be aware of your hands and feet to ensure they don’t get caught.

- Never try to board or descend a piece of machinery that’s moving or in use.

- Remain seated while operating the machinery — don’t lean out of the equipment or hold on with one hand.

- Keep yourself free from distractions while operating heavy machinery and focus on the task at hand.

Become a Forklift Safety Specialist to learn what training your team needs when operating forklifts and how to choose the safest equipment for your job site.

Following Chemical Safety Procedures

Construction sites contain all manner of substances from mild irritants to deadly chemicals, and any safety plan for the construction site must address how to safely store and use them and what to do in the event of a spill.

Some chemical safety precautions include:

- Any chemicals used on the site should be clearly and properly labeled.

- Workers should not handle chemicals without the proper labeling and should report any unlabeled chemicals they find.

- Chemicals should be properly stored according to their attributes — some need to be stored away from heat, and all should be secured in a place where unauthorized people cannot access them.

- Many chemicals should only be used with proper ventilation.

- When dangerous chemicals must be used, only those properly trained in their safety should be permitted to handle them.

- Always use suggested PPE when handling chemicals.

- All chemical spills should be reported, whether they are low-risk or high-risk.

- In the event of a spill, determine the severity and danger of the chemical involved before taking action to have it safely cleaned up.

- In the event of a hazardous chemical spill, evacuate the area immediately and contact qualified professionals to deal with the issue.

- When in doubt, assume a chemical poses a threat.

- Understand that many chemicals found on the construction site produce toxic vapors that are odorless, and some even anesthetize the nose and mask odors.

- If it is possible to do so without risking your safety, remove any sources of heat, flame or electricity around the spill area to reduce the risk of fire or explosion.

- Never touch any chemical with your bare hands, and when in doubt, use additional PPE.

Take our Spill Containment Specialist course to learn more about how to protect your workplace from chemical spills.

Ensuring Trench Safety

Trenches and excavation are an integral aspect of many jobs, and by taking the proper precautions, trench work can be conducted safely without incident nearly every time. When working in trenches, remember:

- Trenches deeper than four feet must have either protective sloping or protective shoring.

- Never enter an unsupported or improperly sloped trench.

- Trenches must be equipped with safe exits like ladders, stairs or ramps at regular intervals along the trench.

- Keep exits free from debris or other blockages and ensure they are easily accessible at all times.

- At least one worker should remain outside the trench at all times to observe and warn their coworkers of shifting soil or other possible dangers.

- If trenches are 20 feet deep or deeper or venture beneath a foundation or wall, a certified expert engineer must design and implement a support system for the trench.

Become a Trench and Excavation Specialist to keep your team safe when performing work in trenches.

Using PPE and Other Equipment for Construction Safety

Every construction safety program should include training workers on when and how to use PPE or personal protective equipment. Some of the most common PPE to be found on construction sites includes:

- Hard hats: Hard hats serve a pretty obvious function around the job site. They should be worn any time there’s a risk of being struck by objects.

- Safety goggles: These protect eyes from chemicals and foreign objects.

- Gloves: Construction workers may need various types of gloves. Disposable nitrile gloves offer protection from mild chemicals, while heavy leather gloves protect against heat, flame, sharp objects and puncture wounds.

- Fall protection gear: Safety harnesses can prevent a serious fall injury when working at a significant height.

- Respirators: Disposable and reusable masks protect against chemicals, dust and debris, especially in areas with poor ventilation.

- Footwear: Non-skid footwear is necessary on almost every site, especially when working on wet surfaces, ladders, scaffolding and slopes. It’s also critical when lifting or working near heavy materials.

- First aid kits: First aid kits should be available and easy to reach by all workers.

- Specialty PPE: Depending on the nature of the work being done, many more protective items could be required. Refer to your construction safety program for more information.

Take our Personal Protective Equipment Specialist course to learn how to ensure proper safety equipment is available on site and used properly.

OSHA Construction Safety Standards

OSHA requirements for the construction industry are in place to protect workers. Keep in mind that OSHA guidelines for construction safety also change. Anyone who works in the construction industry will interact with OSHA eventually, so it’s important to understand what this agency is, its rules and regulations, and how to stay compliant.

Who Is OSHA?

As many in the construction industry are aware, OSHA is the Occupational Safety and Health Administration. It was formed in 1970 through the Occupational Safety and Health Act. The agency’s mission is “to ensure safe and healthful working conditions for workers by setting and enforcing standards and by providing training, outreach, education and assistance.” In plain language, OSHA is the governing body that will ensure your company follows all required safety practices and meets OSHA construction safety standards, which includes providing the necessary training to your workers.

How Can Construction Companies Stay OSHA Compliant?

OSHA standards for the construction industry are extensive and rigorous, and they cover a wide range of construction site safety topics as well as general safety topics. You will likely need to devote a fair amount of time to learning to navigate them. A Certified Safety Manager: Construction course can give you an in-depth understanding of the requirements and break down OSHA rules into plain language while showing you how to apply them in your workplace. A very abridged list of what construction companies must do to remain OSHA compliant includes:

- Observe OSHA’s requirements for specific construction-related hazards: You will not be surprised to learn that these hazards include falls, stairways and ladders, scaffolding, electrical and trenching. OSHA maintains very strict requirements related to each of these, and you are expected to know them and comply fully.

- Observe additional requirements that may apply to your job site: In addition to the standard construction site requirements, your site may have other OSHA requirements to meet. These requirements might include chemical use, silica, concrete and masonry, cranes, derricks, hoists and elevators, welding and brazing, confined spaces, steel erection and residential construction.

- Survey your workplace for any additional hazards: OSHA provides the OSHA Hazard Identification Training Tool and OSHA Safety and Health Bulletins to help you identify hazards at construction job sites. You will need to identify and address hazards such as carbon monoxide, asbestos, heat, lead and other toxic metals.

- Develop a job site construction safety program: OSHA requires companies to design and implement an accident prevention program and regularly inspect tools, workspaces, materials and PPE.

- Train your employees: This training must meet OSHA’s training requirements. For example, as the trainer, you may need to take the associated Train the Trainer courses before training your team.

- Keep records and report all serious injuries and fatalities: Job site fatalities must be reported to OSHA within eight hours, and serious injuries that require hospitalization must be reported within twenty-four hours.

- Display the OSHA poster prominently at the job site: Or, in the case of construction work where the job site can vary from day to day, post it in the place where employees report for work each day. It must be posted in English, Spanish and other languages as needed.

You can find more compliance assistance information on OSHA’s Construction Industry page.

Construction Safety Training

Keeping yourself, your coworkers and your employees safe from injuries isn’t such a monumental task when you’re properly trained for it. The National Association of Safety Professionals offers various courses for safety professionals to sharpen their skills and keep their workplaces safe. They can take these professional development courses to learn how to design safety programs for their workplace as well as to learn proper training techniques to educate their workers. Click here to see our expansive list of construction-related specialist courses.

How Can Construction Companies Facilitate Proper Construction Worker Safety Training?

Training workers on construction safety management isn’t just necessary to shield them from injuries — it’s an OSHA requirement.

Many NASP courses can prepare you to conduct proper safety training for your workers, including:

- Certified Safety Manager: Successful completion of the Certified Safety Manager: Construction (CSMC) course authorizes certificate holders to hold 10-hour and 30-hour construction industry safety training courses. As a CSMC, you may also issue NASP diplomas and pocket cards to your workers as a record of their training.

- HAZWOPER Train-the-Trainer: OSHA requires that professionals complete a HAZWOPER train-the-trainer program before training their workers in Hazardous Waste Operation and Emergency Response.

- Hydrogen Sulfide Safety Train-the-Trainer: OSHA requires that trainers complete a train-the-trainer course in hydrogen sulfide before training employees who will come into contact with this substance.

Purchase NASP’s Construction Safety Courses Online

NASP offers online safety courses, to earn certificates like Safety Director, Aerial and Scissor Lift Specialist and many others. These courses range from eight hours to over two hundred hours, and they cover topics from broad to very specific, so no matter the safety issues you want to explore, you will find a course to meet your needs.

For more information on our full catalog of safety courses, we encourage you to peruse our course offerings and read through our frequently asked questions. Please feel free to reach out to us if you cannot find the answer to your question. We look forward to assisting you and your team with your construction safety training needs.