What Is Ergonomics?

Ergonomics is all about understanding how humans interact with various systems in their environment. In any setting, people face different products, tools, systems, and methods that shape how they function individually or in groups. Depending on their design and capabilities, these tools can be a help or a hindrance.

Ergonomic safety focuses on optimizing systems and other elements to keep people safe and healthy. Most often, ergonomic safety concerns the workplace. It involves how positions and situations at work affect the body, from the chair employees sit in, to the way they lift heavy boxes. More specifically, ergonomic safety ensures a worker’s tools and environment fit their job requirements and personal capabilities.

The employee is always the priority, and companies constantly look for ways to redesign equipment and offices to promote safety and better habits and conditions. The goal with ergonomics is to match the workplace to the employee, not the employee to the workplace!

Employees spend much of their time in the workplace, and ergonomics is related to safety. Ergonomic disorders are a growing category of work-related injuries. Ergonomic safety practices were developed to minimize those risks. When you use ergonomics to study people in their work environment, you’ll find better solutions to reduce injuries, increase employee satisfaction and productivity, and create a better, happier environment for everyone.

What Is the Goal of Ergonomic Safety?

Ergonomic safety is a broad concept that encompasses a wide range of goals. However, the most essential objective of these practices is to design, modify, or improve the work to fit the worker — not the other way around. Ergonomics seeks to ensure there’s always a good fit between employees and the job conditions, demands, and environment in which they work.

Every industry has specific risks, and it’s the employer’s job to mitigate them. When you take greater responsibility for your workers’ safety, health, and comfort, you can lessen muscle fatigue, reduce the number and severity of work-related injuries, and increase productivity and satisfaction.

Implementing ergonomic safety best practices are necessary to counter various risk factors and potential hazards at work. You’ll be able to reduce the risk of painful cumulative damage or stress among workers and maintain a stronger, more engaged workforce.

Ergonomic Risk Factors

When you walk into any office or jobsite, you’re likely to find ergonomic-related risks and potential areas of improvement wherever you look. Since ergonomics deals with all the systems people encounter in their workspace, you can view every part of the workplace through an ergonomic safety lens. Each step of the process is an opportunity to reduce musculoskeletal disorders (MSDs) and keep workers safe.

Most commonly, ergonomic safety considers the physical demands a worker faces. It encompasses whether those requirements are within the employee’s purview to the tools and methods they use to perform their tasks. The most widespread ergonomic risk factors include:

- Repetitiveness: Repetition is one of the top causes of work-related injuries and strain. Repeated tasks, including typing at a desk and using the same wrist motions all day long or frequently lifting materials in the same way, put a strain on your body. This wear and tear adds up over time and may lead to MSDs or other injuries.

- Required force: Consider how much force or strength is required to perform certain tasks, such as carrying boxes or loading trucks and pallets. Overtaxing your employees can quickly lead to injuries, lost time, and a more stressful workplace. Instead, ensure that physically demanding tasks fit within each employee’s capabilities and job responsibilities.

- Prolonged positions: Just as a physically active role can cause injuries, static work poses significant risks to workers, too. Far too many office workers are familiar with back pain after spending their day in an uncomfortable or inadequate office chair. Sitting or standing in the same place or position, maintaining an awkward posture, and performing prolonged or excessive tasks all strain parts of your body.

- Inadequate tools: Workers often rely on computers, machines, industrial equipment, and other tools to get the job done. If these products are broken, outdated, or otherwise substandard, employees are at a greater risk for ergonomic disorders and injuries.

In addition to physical job demands and the tools they use, workers are also susceptible to external risks in their workplace. For example, extreme hot or cold temperatures on a job site, constant vibrations, or other uncomfortable environments can lead to cumulative damage that harms workers over time.

Common Ergonomic Injuries

All of these risk factors caused ergonomic safety to develop. Risks can lead to ergonomic injuries, which can vary from headaches or tension in the neck after a long day to serious, long-lasting musculoskeletal disorders.

The type and severity of potential injuries depend on your industry and the risk factors mentioned above. However, the most common ergonomic injuries due to repetitive, forceful, or awkward work include:

- Musculoskeletal disorders: These wide-ranging conditions affect your bones, joints, ligaments, tendons, and other parts of your muscles and skeleton. MSDs can be acute injuries, like fractures or chronic conditions that last for a long time. Workplace musculoskeletal disorders (WMSDs) are conditions caused by your job responsibilities or other work tasks.

- Carpal tunnel syndrome: One of the most common types of musculoskeletal disorders, carpal tunnel syndrome occurs when the median nerve in your wrist is pinched by the tendons that sheath a series of carpal bones (that form a tunnel), leading to numbness, weakness, and pain in your hand, wrist, and arm. Repeating the same motions or prolonged use, such as typing on a keyboard for long periods, can lead to carpal tunnel syndrome.

- Muscle strain: A number of activities or motions can lead to muscle strains and pain throughout your body, including your neck and between the shoulders.

- Rotator cuff injuries: Your rotator cuff is the area around your shoulder, including the muscles and tendons. While acute injuries like rotator cuff tears are possible, gradual degeneration caused by the wear and tear of repetitive motions at the workplace are common WMSDs.

- Lower back injuries: Whether a worker is lifting heavy boxes or sitting in the same position all day, lower back injuries are widespread on the job, and more commonly affect men. Proper lifting methods or posture correcting can help minimize back pain and complications.

- Eye strain: Looking at a computer screen or other electronics for several hours a day can put stress on the eyes, especially without adequate breaks.

Preventing Ergonomic Hazards in the Workplace

Ergonomics involves fitting the task to the worker, and a significant part of that is assessing the potential risk factors and finding solutions. By making ergonomic changes before tasks are done, you can prevent unnecessary strain, which causes injuries and MSDs. Here are six tips to prevent ergonomic hazards in a construction workplace:

- Promote hand and wrist safety: Reduce tasks that require repeated hand or wrist-twisting motions. If such motions are needed, provide the proper hand tools that allow workers to perform the necessary functions while keeping the hand in a neutral, comfortable position.

- Protect the back when weight lifting: Use a buddy system when employees lift heavy loads to distribute the weight more evenly. Educate workers on the safe way to lift by propelling with the legs instead of the upper body.

- Prevent strain from overhead work: Avoid activities requiring excessive overhead stretching. If necessary, adjust the scaffolds to meet the proper working height and utilize a lifting device to make it easier to hold the material in position for overhead work.

- Protect workers from vibration: Pair vibrating tools with gloves to absorb the energy or use specialized tools to dampen the vibrating energy.

- Prevent knee strain: Design work tasks so workers don’t have to strain their knees by kneeling extensively. If the job requires such tasks, knee pads can protect them.

- Reduce repetitiveness: Repeated actions can cause strain on certain muscle groups or joints. To prevent injuries, rotate tasks between workers.

How to Spot Ergonomic Hazards and Fix Them

Improving your workplace ergonomics and health and safety requires spotting hazards or potential issues and fixing them. Always keep in mind the leading principle of ergonomics — designing and modifying work to better suit your workers and their capabilities. You’ll learn to prevent injuries, improve satisfaction, and boost productivity.

Learn more about how you can implement ergonomic safety best practices in three areas — office workstations, physically demanding tasks, and on a managerial level.

Workstation Improvements

Nine to five office workers are susceptible to ergonomic disorders. Fortunately, there are several solutions you can implement to keep your workplace safe. Some improvements are tools you can provide for your employees, while others are steps they can take themselves with adequate training:

- Redesigned tools and adjustable equipment: Modify chairs, desks, keyboards, and other equipment to offer the maximum level of comfort and functionality possible. Employees should be able to adjust their space in a way that makes the most sense for each individual. For example, a tall employee will likely need a different chair or desk height than a shorter worker to prevent back pain or other MSDs.

- Work close to the body: Certain postures and movements put less wear and tear on your body than others. When you work at a desk that allows you to sit comfortably with enough padding, see the screen easily, and maintain neutral joint positions, you’re more likely to avoid excessive strain or tension.

- Avoid eye strain: Taking regular breaks from looking at a screen can reduce the stress electronics place on your eyes.

- Alternate postures and motions: Even if you follow ergonomic best practices as you work, holding the same position all day strains your body. Encourage employees to change their postures and motions from time to time and give them adequate breaks to stretch and relax.

- Keep the workspace clean and clear: A neat workspace is easier to navigate, less prone to hazards, and boosts office morale to reduce stress.

Handling Physically Demanding Tasks

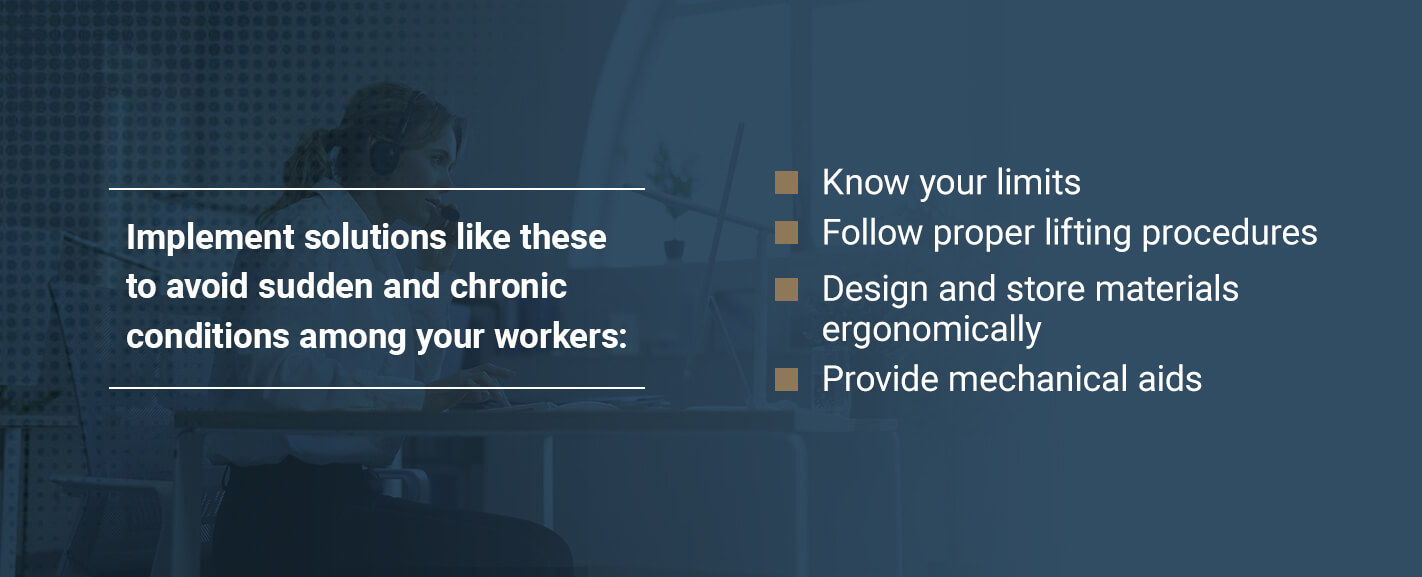

Many workplace injuries occur when employees attempt active and demanding tasks, especially in industrial fields that require physical labor. Implement solutions like these to avoid sudden and chronic conditions among your workers:

- Know your limits: Using guidelines and evaluations, ensure you and your employees know their capabilities and limitations. No worker should exceed their advised limits. Label all loads with the correct weight to ensure everyone understands the requirements for every job.

- Follow proper lifting procedures: When handling or transporting materials or goods, avoid bending forward, twisting your trunk, reaching excessively, or lifting above shoulder height. These actions put you at a higher risk for back injuries and WMSDs.

- Design and store materials ergonomically: Properly storing products or goods makes it easier for workers to avoid harmful actions or tasks like those mentioned above. Keeping boxes above waist height but below your shoulders makes it easier to move objects.

- Provide mechanical aids: Industrial tools help workers perform tasks so they don’t have to manually lift, push, pull, and handle heavy materials manually. Provide carts and other mechanical aids for your employees.

Managerial Ergonomic Strategies

You can tackle ergonomic safety at every level. Focusing on ways you can improve your workers’ safety and comfort through supportive policies, better scheduling, and other beneficial managerial decisions can have a considerable impact:

- Identify problems proactively: The first step in solving a problem is defining it. Involve your workers in the process, inviting them to share their experiences and areas where they feel ergonomic safety could be improved. You should also encourage early reporting of MSDs and other workplace-related injuries so you can address problems before they become more severe.

- Provide clear guidelines, training, and resources: Proper education about ergonomic safety methods and habits goes a long way toward protecting your employees. Workers can implement the strategies they learn into their unique routines and adjust as necessary, depending on what’s best for them. Providing clear standards ensures everyone is on the same page.

- Staff scheduling: When and how your employees work plays a significant role in their ergonomic safety. Rotate workers between tasks to avoid repetitive tasks that can cause muscle strain. You should minimize excess overtime when possible, schedule regular breaks, and keep an adequate number of workers on hand to reduce individual workloads.

- Evaluate progress regularly: Workplace ergonomic safety is an ongoing process. Check in routinely to determine where your solutions have succeeded and areas you can work to improve next.

Ergonomic Solutions for Different Work Levels

Workers on different levels are exposed to unique ergonomic pressures, so they require tailored solutions to provide the ultimate physical support. Overhead, floor, and ground-level work are necessary for most construction tasks, but they come with several risks.

Floor and Ground-Level Work

Many construction tasks require bending, squatting, or kneeling when working on the floor or at ground level. Prolonged bending for months can lead to herniation, and continued knee stress can negatively affect the tendons. Here are some solutions:

- Change tools and equipment: Workers should have extendable tools to prevent strain from bending down.

- Choose different materials and work processes: Workers commonly use the floor as a makeshift bench and a space for assembling and mixing. Rather than bending down, use tables and sawhorses to keep tasks at an ergonomic level.

- Use ergonomic-focused rules: Implement rules that make it easier for workers to work safely, such as requiring all equipment to be stored off the ground to prevent excessive bending.

Overhead Work

Certain construction jobs require overhead work, which involves reaching one or both arms above the shoulders. Prolonging this position can cause stress on the shoulders, causing tenderness, stiffness, and inflammation. Here are three solutions to improve ergonomics in overhead work:

- Pick different materials: Use materials that are less labor intensive. For instance, you could install embedded concrete inserts on ceiling forms so workers don’t have to drill overhead for a long time.

- Switch equipment: Use tools that allow you to hold them at waist level instead of reaching overhead. You could also use mechanical hoists to keep them in a raised position or lift them yourself.

- Take breaks: To prevent strain, limit the amount of time that employees perform overhead tasks or encourage short breaks to prevent strain.

Benefits of Ergonomic Safety

Ergonomic injuries are the most costly and prevalent in the workplace, accounting for almost as many lost workdays as the common cold. Understanding what ergonomics in the workplace is helps you reap the endless advantages for your business. Check out these benefits and discover more when you begin applying ergonomic best practices at your workplace:

- Prevent MSDs: The clearest advantage of a safer, more comfortable workplace is fewer musculoskeletal disorders and related injuries. Employees will be less susceptible to painful, sometimes chronic conditions that may affect their work and lives.

- Avoid other injuries and accidents: When your employees are aware of ergonomic risks, their awareness expands to other potential hazards in the workplace. Mindful workers are more likely to stay on track and prevent accidents.

- Reduce costs: Preventing costly MSDs and downtime can significantly reduce your company’s expenses and improve cost savings. With the increased productivity that comes from happier workers, you’ll see an increased bottom line, too.

- Foster engagement and satisfaction among employees: A safer workplace is a happier workplace. Comfortable and safe employees will be more engaged with their work, especially if they feel they’ve played a part in improving the office’s ergonomic policies for everyone.

- Improve overall productivity: Healthy and comfortable workers who follow proper procedures can get more done. Ergonomics will boost your output and overall productivity.

Why Is Implementing an Ergonomic Protection Program Important?

Whether most of your employees work in an office, from home, or at a job site, ergonomic safety has never been more essential. With workplace musculoskeletal disorders on the rise, it’s your job as an employer or safety manager to implement policies and procedures that keep your workers safe and comfortable.

Experts constantly develop new ergonomic safety practices based on the latest data to create better workspaces. Thanks to ergonomics, your possibilities for growth are endless with happier workers and a stronger business.

Features of an Effective Ergonomics Program

An effective workplace safety ergonomics program is a necessity to educate workers on reducing physical stress. Here are some of the features it should have:

- The full commitment of all employees.

- A structured system to pinpoint and analyze risk factors.

- Accessible medical care for injured workers.

- A comprehensive record to maintain instances of ergonomic-related injuries.

- A consistent evaluation and a feedback platform for the program’s effectiveness.

- An administrative structure, such as a committee.

Purchase NASP’s Ergonomic Safety Course

If you’re looking to improve your company’s ergonomic safety and overall well-being, the National Association of Safety Professionals (NASP) is here to help. We offer workplace safety training for a wide range of industries, from construction and oil and gas to government agencies. Our professional certificates, consulting services, and classroom, online, and site-specific training will improve your employee safety in any environment.

Our Workplace Ergonomic Specialist (WES) course offers a thorough education on workplace ergonomic safety, common types of MSDs, identifying potential issues and risk factors, the importance of an ergonomics program, and ways to implement successful and effective strategies. Purchase our WES course to get started, or contact NASP for more information today.

Blog Posts

Latest Posts

Related Posts