OSHA Standards for Crystalline Silica

The Occupational Safety and Health Administration (OSHA) crystalline silica requirements are designed to protect workers from the harmful effects of exposure in the workplace. In the United States, 2.3 million people are exposed to crystalline silica during their work. Respirable crystalline silica dust is a recognized health hazard, and employers are responsible for keeping their workers protected.

Respiratory protection was the third-highest OSHA violation in 2022. There are many other considerations for employers when protecting their workforce from the harmful effects of crystalline silica and staying compliant with OSHA regulations.

What Is Crystalline Silica?

Crystalline silica is an abundant natural material in soil, sand, and other earth crust elements. Many construction materials contain crystalline silica, including concrete and mortar, and it’s also used to make ceramics, glass, bricks, and artificial stone. Quartz is the most common form of crystalline silica, although several other forms exist across industries.

Silica dust — or respirable crystalline silica — comprises tiny particles created when cutting, sawing, drilling, grinding, and crushing rock and stone. Exposure to these tiny particles occurs in many industries. Workers often inhale silica dust when partaking in the abovementioned activities.

What Are the Hazards of Working With Crystalline Silica?

The OSHA crystalline silica regulations are stringent, with good reason. Exposure to silica dust can result in multiple health complications and is related to the development of autoimmune disorders and cardiovascular impairment. Some of the common health effects of exposure to crystalline silica dust include the following:

- Silicosis: This illness can be disabling and fatal in some cases. It’s caused by silica dust entering the lungs and creating scar tissue, which impedes the lungs’ ability to take in oxygen. Silicosis also affects the immune system and increases the risk of lung infections and tuberculosis. The illness often occurs after 15-20 years of occupational exposure to silica dust.

- Lung cancer: Exposure to crystalline silica is linked with elevated lung cancer Lung cancer cells can metastasize and affect other parts of the body.

- Kidney disease: Workers exposed to crystalline silica are at increased risk of developing kidney disease. In some cases, they suffer complete kidney failure.

- Chronic obstructive pulmonary disease (COPD): Crystalline silica exposure increases the risk of lung disease, primarily COPD. This disease is characterized by shortness of breath, which may worsen.

What Is the OSHA Crystalline Silica Standard?

Under the OSHA respirable crystalline silica rule, employers are responsible for ensuring their workers are protected from exposure to crystalline silica. OSHA has released two standards to protect workers — one for construction and one for general industry and maritime. These different standards allow employers to create specific solutions for their workplaces.

The OSHA crystalline silica regulations are detailed and exhaustive, but some of the main requirements include the following:

- Limit and protect: OSHA requires employers to limit worker exposure to respirable crystalline silica. OSHA crystalline silica exposure limits are 50 µg/m3 — 50 micrograms per cubic meter of air — as an eight-hour time-weighted average (TWA). This amount is believed to be the maximum workers can endure without experiencing adverse health effects.

- Implement a written exposure plan: Employers must conceive and implement a written exposure plan identifying tasks that expose workers to silica dust and the methods they can use to protect themselves. The exposure plan must include procedures restricting worker access to high-exposure areas.

- Designate a competent person: Organizations must assign a qualified person to oversee the implementation of the written exposure plan.

- Restrict exposure: Employers and safety managers must restrict housekeeping practices that expose workers to crystalline silica wherever a feasible alternative exists.

- Provide medical exams: Workers required by the standard to wear a respirator for more than 30 days a year must have medical exams every three years, including chest X-rays and lung function tests.

- Keep records: Employers must keep detailed records of silica exposure and medical exams.

- Train workers: Employers must provide training for any work involving silica dust exposure and methods to limit the exposure.

How Can You Protect Workers When Working Around Crystalline Silica Dust?

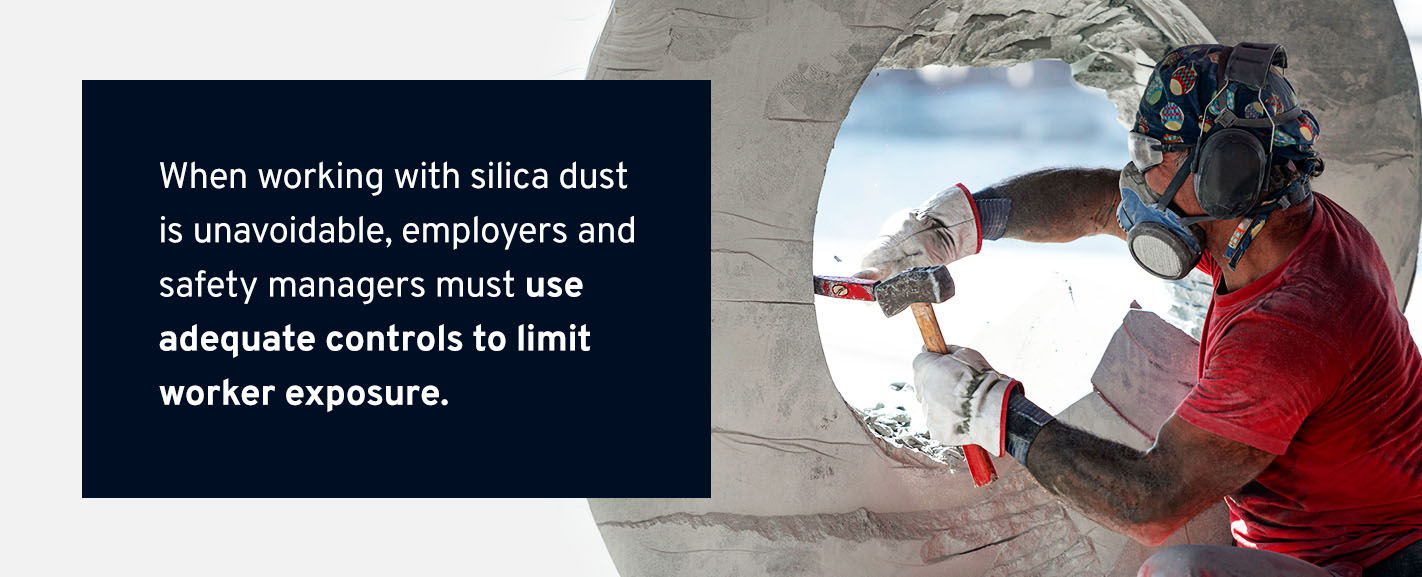

When working with silica dust is unavoidable, employers and safety managers must use adequate controls to limit worker exposure. Some of the methods for protecting employees include the following:

- Following OSHA dust control methods: Employers and competent persons must ensure workers follow dust control methods outlined in the OSHA compliance guidelines for their industry.

- Using wet methods: Use methods that apply water at the impact site where dust is generated to minimize the dust particles in the air.

- Removing silica dust: Use local ventilation methods at the site where dust is generated.

- Isolating the work process: Keep the areas where silica dust is present isolated using enclosures.

- Combining water and ventilation controls: A combination of water and ventilation is an excellent solution if effective in a particular application.

- Providing respiratory protection: Employers must provide workers with the appropriate personal protective equipment (PPE) when working with silica dust, such as a tight-fitting respirator with an effective seal. Workers must use respiratory protection in areas where the silica dust is above the permissible exposure limits.

- Ensuring all control measures are effective: Safety managers must check that the preventive measures in place — water and ventilation — are working correctly and regularly replace air and water filters.

Training for OSHA’s Crystalline Silica Program

The OSHA crystalline silica program requires workers to train for at least one full hour when they work with silica dust. Training for respirable silica is performance-based, which means that during an OSHA inspection, inspectors will assess employees based on their ability to demonstrate their knowledge of the rules and safety protocols.

All employees in a workplace covered by the silica rule require training. The minimum knowledge and understanding of crystalline safety include the following:

- The health hazards associated with exposure to silica dust,

- Tasks in the workplace that could result in exposure,

- Measures the employer has taken to protect employees from exposure, including engineering controls and PPE, and

- The purpose of the medical surveillance program and what the program entails.

OSHA guidelines state that the employer is best positioned to determine effective training. Training can therefore include anything employers consider necessary to promote safety in the workplace.

Protect Your Workers With NASP Today

Protecting workers from the harmful effects of crystalline silica exposure is essential for employers and safety managers assigned to implement written exposure plans. OSHA requires all employees to be trained to keep themselves and others safe. The National Association of Safety Professionals (NASP) offers The Practical Approach to Workplace Safety, helping you maintain compliance and worker safety.

NASP offers workplace safety training for many industries and applications. Our silica dust specialist (SDS) course will equip you with the knowledge and expertise to create workplace safety and meet or exceed OSHA regulations. Contact us today to learn more about our courses and safety certificates, made by and for safety professionals.

Blog Posts

Latest Posts

Related Posts