National Ladder Safety Month

Falls from ladders are a leading cause of workplace fatalities, making ladder safety a critical concern for employers and employees alike. In recognition of this risk, March is designated as National Ladder Safety Month, an initiative spearheaded by the American Ladder Institute (ALI) to promote safe ladder practices both at work and home.

Falls are consistently one of the most common causes of workplace fatalities. According to the Bureau of Labor Statistics (BLS), in 2023, falls, slips, and trips accounted for 885 fatal work injuries across all sectors in the United States. Within the construction industry, falls, slips, and trips were responsible for a staggering 39.2 percent of all Construction-related deaths. The majority (64.4 percent) of fatal falls in construction were from a height of 6 to 30 feet, while those over 30 feet accounted for 16.6 percent.

Ladders themselves are a significant factor in fall-related injuries and deaths. In 2023, portable ladders and stairs were the primary cause of 109 fatal work injuries. OSHA’s ladder regulations consistently rank among the agency’s top ten most frequently cited violations, highlighting the ongoing need for improved ladder safety practices.

To prevent ladder-related accidents, it’s crucial to follow safety guidelines. Here are some key steps for ladder safety:

1. Select the Right Ladder for the Job:

- Ladder Type: Choose the correct ladder type (step ladder, extension ladder, etc.) based on the task and the height needed. For example, a step ladder can be used for tasks at lower heights and an extension ladder can be used to reach higher areas.

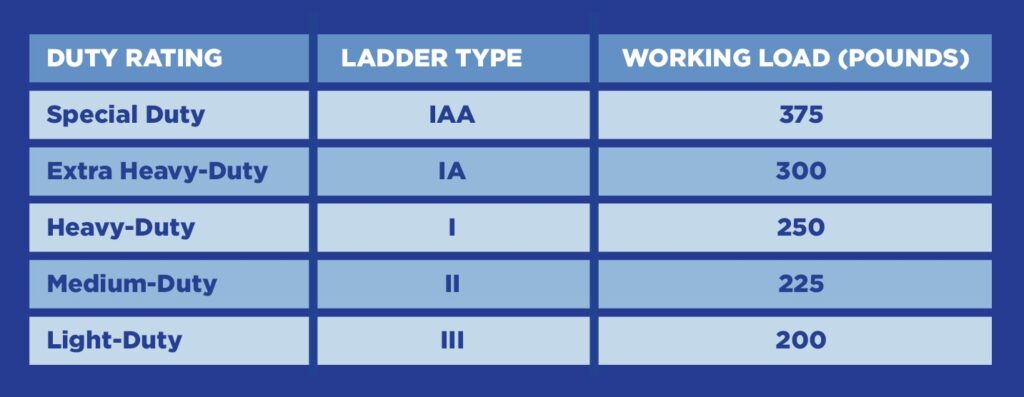

- Duty Rating: Ensure the ladder’s duty rating (Type IAA, IA, I, II, or III) exceeds the total weight of the user, tools, and materials. Heavier-duty ratings are for heavier loads.

- Material: Based on the environment, select the appropriate ladder material (fiberglass, aluminum, wood). Fiberglass ladders are non-conductive and safer for electrical work.

2. Conduct Thorough Inspections:

- Pre-Use Inspection: 29 CFR 1910.23(b)(9) requires ladders to be inspected before each use during each shift and more frequently if necessary. Inspect the ladder for any visible defects, such as:

- Damaged or missing rungs, steps, or cleats.

- Loose or damaged side rails.

- Damaged or worn safety feet.

- Cracked or bent components.

- Loose or missing hardware.

- Frayed or worn ropes or cables (on extension ladders).

- Regular Maintenance: Ladders must be maintained in good condition at all times. The joint between the steps and side rails must be tight, all hardware and fittings must be securely attached, and moveable parts must operate freely without binding or undue play. Metal ladders must not be exposed to acid or alkali materials, which could corrode them and degrade their stability and strength. Follow the manufacturer’s periodic maintenance and inspection recommendations.

- Remove Damaged Ladders: Immediately remove any damaged ladder from service and tag it “Do Not Use” until it is repaired or replaced.

3. Set Up the Ladder Correctly:

- Stable and Level Surface: Place the ladder on a firm, level, and non-slippery surface. Avoid uneven ground, soft surfaces, or surfaces covered in debris. Use ladder levelers or base adjustments if necessary.

- Proper Angle for Extension Ladders: Set up extension ladders at a 75-degree angle. A simple rule of thumb is the 4-to-1 rule: for every 4 feet of working height, the ladder’s base should be 1 foot away from the wall or support.

- Secure the Ladder: Secure the ladder to prevent it from slipping or falling.

- Tie-Off: Tie off the top of extension ladders to a stable support, especially when accessing a roof or elevated platform.

- Ladder Stabilizers/Outriggers: Use ladder stabilizers or outriggers for added stability, especially for wider ladders or when working on uneven surfaces.

- Footing: Use non-slip ladder feet or place the ladder feet on a non-slip surface.

- Extension Above Landing: When using a ladder to access an upper landing, extend the ladder at least 3 feet beyond the landing point to provide a handhold for getting on and off the platform safely.

4. Practice Safe Climbing Techniques:

- Three Points of Contact: Always maintain three points of contact with the ladder while climbing or descending (two hands and one foot, or two feet and one hand).

- Face the Ladder: Always face the ladder when climbing up or down.

- Climb Slowly and Deliberately: Avoid rushing or making sudden movements on the ladder.

- Center of Gravity: Keep your body centered between the ladder’s side rails. Avoid leaning or reaching too far to the side, which can cause the ladder to tip over.

5. Avoid Unsafe Practices:

- Do not stand on the top step or cap of a stepladder or the top three rungs of an extension ladder. These are not designed for standing and can be unstable.

- Do not exceed the ladder’s maximum weight capacity. Consider your weight, your clothing, your tools, and your materials.

- Do not overreach while on the ladder. Descend and reposition the ladder closer to your work area instead.

- Never use the cross-bracing or rear section of step ladders for climbing unless the ladder is designed for this and allowed explicitly in manufacturer instructions.

- Never use ladders as a brace, skid, guy or gin pole, gang-way, or any other use other than the way intended and instructed by the manufacturer.

- Never Move a Ladder While in Use, always descend and reposition the ladder instead of attempting to shift it while someone is on it.

- Be Aware of your Surroundings:

- Electrical Hazards: Be aware of overhead power lines and electrical sources. Use fiberglass ladders when working near electricity.

- Traffic: If working near pedestrian or vehicle traffic, use barriers or cones to create a safe work zone.

- Weather Conditions: Do not use ladders in high winds or during storms. Ladders can become unstable in windy conditions, and surfaces can become slippery in wet weather.

6. Proper Training and Supervision:

- Ladder Safety Training: Provide comprehensive ladder safety training to all employees who use ladders, covering ladder selection, inspection, setup, safe use, and storage.

- Supervision: Ensure adequate supervision to enforce safe ladder practices and address any unsafe conditions.

By consistently following these safety methods, you can significantly reduce the risk of ladder accidents and create a safer working environment.

While ladder safety is paramount, it’s important to remember that falls in the workplace can occur from various walking and working surfaces, not just ladders. These include slips and trips on floors, falls from scaffolding, mobile equipment, work platforms, roofs, and other elevated surfaces. Maintaining safe walking and working surfaces through good housekeeping practices, proper fall protection measures, and comprehensive training is essential for preventing workplace falls and ensuring worker safety across all environments.

Blog Posts

Latest Posts

Related Posts