Hand-Arm Vibration Syndrome

Hand-arm vibration syndrome is a silent disorder affecting many workers who do physical labor. Safety professionals must understand this condition to safeguard the workforce’s well-being.

According to the International Organization for Standardization, about 50% of workers exposed to vibrations may develop HAVS. This alarming statistic deserves more attention, as this illness may worsen over time without preventive or corrective measures.

With help from our article, we hope you can raise hand-arm vibration syndrome awareness in the workplace. With this guide, you’ll recognize typical HAVS symptoms and know how to prevent it.

What Is Hand-Arm Vibration Syndrome?

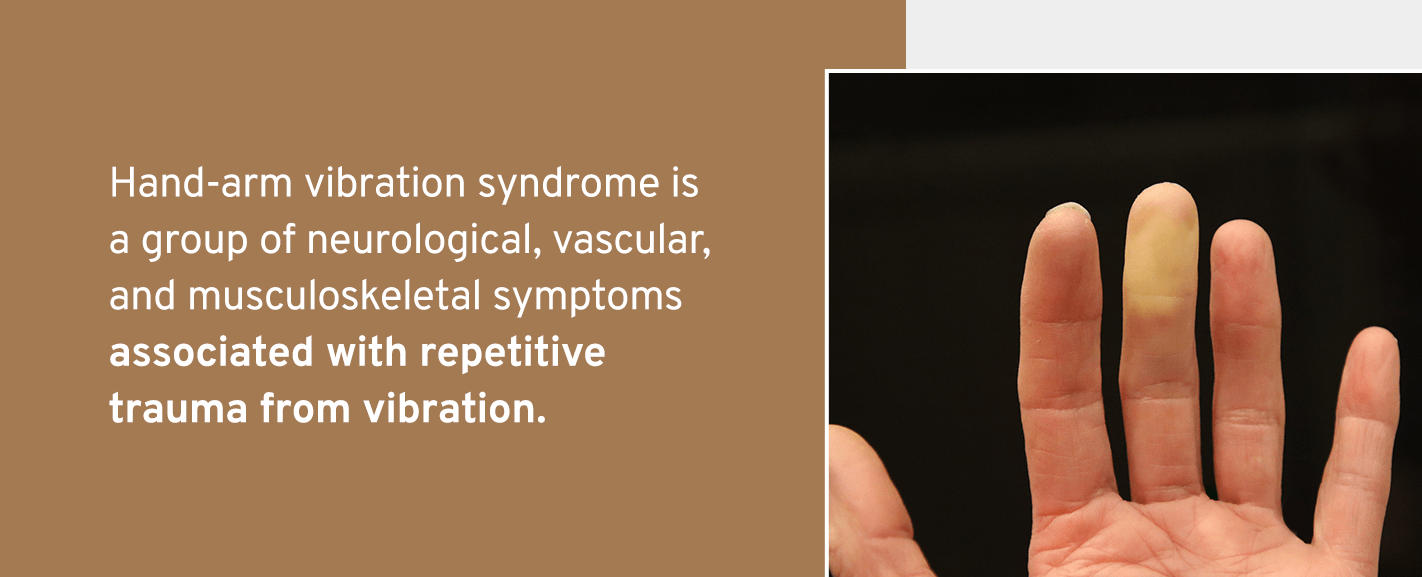

Hand-arm vibration syndrome is a group of neurological, vascular, and musculoskeletal symptoms associated with repetitive trauma from vibration. HAVS can damage nerves, blood vessels, and muscles in the fingers, hands, and arms.

Other names for this condition include vibration white finger and Raynaud’s phenomenon of occupational origin. However, those names do not paint a complete picture, as symptoms can extend beyond the fingers.

HAVS is a prevalent occupational hazard in the construction, forestry, manufacturing, and mining industries. Workers in these sectors are at high risk of developing HAVS when they routinely use pneumatic and electric vibrating tools for their jobs. As a result, they must find a balance between completing their tasks and preventing HAVS.

Types of HAVS Injuries

HAVS falls into three categories, depending on the area it affects. Workers may experience one or a combination of the following types of HAVS injuries.

- Neurological injuries result from damage to the nerve cells in the fingers, hands, and arms. Some early signs of neurological injuries include tingling and numbing, which may reduce hand functionality. Examples include carpal tunnel syndrome and Raynaud’s syndrome.

- Vascular injuries occur when the vibrations damage capillaries in the fingers and hands, causing a vasospasm. As a result, this condition reduces the hand’s blood flow and can cause numbness and blanching of the skin.

- Muscular injuries result from damage to the muscle structure. These can reduce grip strength and hand functionality.

What Causes Hand-Arm Vibration Syndrome?

As you’ve learned, HAVS results from prolonged, repetitive trauma from high-frequency vibration, often caused by power tools and machines like these:

- Chainsaws

- Chipping tools

- Concrete breakers

- Handheld grinders

- Impact wrenches

- Needle scalers

- Polishers

- Pedestal grinders

- Pneumatic drills

- Power drills

- Power hammers and chisels

- Powered lawn mowers

- Powered sanders

- Scabblers

- Strimmers

When someone uses these tools, their fingers, hands, and arms absorb the vibrations, which may cause minor, repeated injuries to tiny nerves and capillaries. Prolonged use of this powered equipment can significantly impact workers’ quality of life and ability to do their jobs.

Some occupations that frequently rely on vibrating tools and machines are more likely to risk HAVS. The following sectors should implement HAVS preventive measures:

- Construction

- Estate management

- Forestry

- Heavy engineering

- Manufacturing

- Mining

- Public utilities

Other factors may also contribute to HAVS. They can include the following:

- Acceleration, duration, and frequency of vibration

- Hand and arm positioning

- Handle texture and softness

- Individual susceptibility to vibration

- Tool maintenance

- Workpiece hardness

- Worker’s grip on the equipment

- Worker’s history of smoking and drug use

- Worker’s medical history of finger, hand, or arm injuries

- Equipment control level

Symptoms of Hand-Arm Vibration Syndrome

Fully developed HAVS is incurable, so employees and employers must know the warning signs to look for before it worsens.

- Constant or intermittent numbness and tingling in one or more fingers

- Weakened grip strength

- Aches and pains in the hands and arms

Continued use of high-vibration tools and machines will exacerbate the symptoms. Here are a few examples:

- Permanent numbness in the fingertips that may extend further along the affected fingers.

- Reduced functionality of fingers and hands, like increased difficulty in performing delicate tasks.

- Frequent blanching or whitening of one or more fingers, as seen in vibration white finger.

The cold may be a primary trigger for vibration white finger attacks. People with VWF may also experience cold and pain in their fingers and hands between episodes.

How Do HAVS Symptoms Progress?

HAVS progression varies from one person to the next. Symptoms may appear within a few months for some, whereas it can take a few years for others.

As these symptoms worsen, they can become irreversible if people do not take preventive measures. Someone may have permanent numbness in their fingers as a result of untreated HAVS. The condition may also lead to weakened hand and arm muscles. Some may have frequent bouts of Raynaud’s phenomenon, especially in milder climates or conditions where their hands sweat more.

Health professionals use the Stockholm Workshop Scale to determine HAVS severity. This system provides a starting point to assess the sensorineural damage done by HAVS by classifying symptoms into five progressive stages.

- Stage 0 (no attacks): The vibration-exposed person shows no signs or symptoms.

- Stage 1 (mild): The worker experiences mild, occasional attacks of intermittent numbness without tingling. Stage 1 affects one or more fingertips.

- Stage 2 (moderate): The person experiences tolerable, periodic attacks of intermittent or persistent numbness. They may also experience reduced sensory perception. Stage 2 affects the distal and middle phalanges of one or more fingers.

- Stage 3 (severe): The worker undergoes severe, frequent, intermittent, or persistent numbness attacks. They may also have reduced tactile discrimination and manipulative dexterity. Stage 3 affects all phalanges of most fingers.

- Stage 4 (very severe): The person experiences the same symptoms as Stage 3, with the addition of trophic changes in the fingertips.

How to Prevent Hand-Arm Vibration Syndrome

Because HAVS is incurable, workers, employers, and safety professionals should focus on improving workplace conditions, changing tool usage habits, and taking other preventive measures.

What Employers Can Do

While OSHA has no standard for vibration limitations in U.S. workplaces, employers can warn their workers about vibration hazards, require them to take frequent breaks, and train them to grip the tools as lightly as possible within reasonable safety bounds.

Employers can also take preventive measures:

- Schedule work shifts or use alternative methods to prevent prolonged and continuous vibration exposures.

- Mechanize or automate work if possible.

- Select alternative tools with lower vibration levels.

- Limit high-vibration tool usage where possible.

- Maintain tools and machines to control vibration levels.

What Employees Can Do

Employees can also take steps to minimize their risk of developing HAVS at work:

- If applicable, complete tasks without vibrating tools.

- Consider using lower-vibration tools.

- Maintain or repair tools before each use.

- Use sharp cutting tools to minimize vibration exposure and maximize efficiency.

- Take intermittent breaks when using high-vibration tools.

- Keep a looser, yet still secure, grip on vibrating tools.

- Wear gloves and other PPE to reduce the vibrational impact.

- Improve circulation by staying warm and dry, avoiding or limiting smoking, and exercising or massaging fingers, hands, and arms during breaks.

- Follow employer-mandated preventive measures.

- Promptly report any HAVS signs and symptoms to your employer and seek medical attention.

Empower Your Safety Arsenal With NASP

Equip yourself with the knowledge and skills needed to combat HAVS by enrolling in the Certified Safety Manager course offered by the National Association of Safety Professionals.

We focus on real-world training built by safety professionals, for safety professionals. NASP’s approach ensures regulatory compliance and cultivates a safety culture within your organization. At NASP, safety isn’t a box to check — it’s a culture to build.

Contact us online for more information about our courses and services.

Blog Posts

Latest Posts

Related Posts